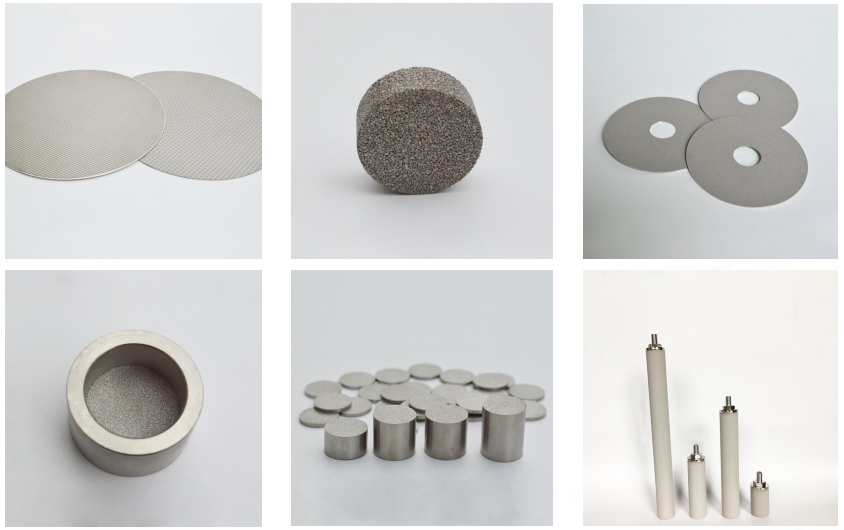

Porous sintered titanium plate Porous titanium plate

Titanium plate powder sintered filter plate

| product | The length of (diameter) | The width of (diameter) | The thickness of the | custom |

| Sintered porous disc | 5-Dia400mm | 5-400mm | 1-20mm | Yes. |

| Sintered porous plate | 1-600mm | 5-400mm | 1-20mm | Yes. |

| Sintered porous plate | 100-1200mm | 20-200mm | 1-10mm | Yes. |

| Sintered porous filter element | 100-1200mm | 20-200mm | 1-10mm | Yes. |

Porous sintered titanium plate porous titanium anode hydroelectrolysis hydrogen production porous titanium plate powder sintered filter plate

Titanium sintered porous material is made of spherical titanium powder with high purity by high temperature forming and sintering. Features: The material contains a large number of connected pores, the pore structure is made up of regular and irregular powder particles, the size and distribution of pores and the size of porosity can be adjusted according to the powder particle size combination and the preparation process to meet the actual needs of customers.

| product | The length of (diameter) | The width of (diameter) | Thethickness of the | custom |

| Sintered porous disc | 5-400mm | 5-400mm | 1-20mm | Yes. |

| Sintered porous plate | 1-600mm | 5-400mm | 1-20mm | Yes. |

| Sintered porous plate | 100-1200mm | 20-200mm | 1-10mm | Yes. |

| Sintered porous filter element | 100-1200mm | 20-200mm | 1-10mm | Yes. |

Properties of titanium sintered porous materials:

1) Uniform pore size, pore stability, separation.

2) High porosity, low filtration resistance and high permeability.

3) Good chemical stability, acid and alkali corrosion resistance, oxidation resistance.

4) Stable form, no particle shedding, in line with food hygiene and drug GMP requirements.

5) Good mechanical properties, low pressure difference, large flow.

6) Strong anti-microbial ability, does not interact with microorganisms.

7) Online regeneration, easy cleaning, long service life.

8) It has good biocompatibility and can be widely used in the field of biology.

4. The application of titanium sintered porous materials

Titanium sintered porous materials are mainly used in filtration materials, electrode materials, heat transfer materials, catalyst carrier materials, noise elimination materials and so on.

1) Decharcoal filtration of drug solution in pharmaceutical industry.

2) Precision filtration and gas distribution in electrolysis gas industry.

3) The medical industry is used to make biological implants.

4) Filtration and ozone aeration after sterilization of odor in water treatment industry.

5) Clarification and filtration in food and beverage processing.

6) Pre-filtration of reverse osmosis system in electronics industry.

7) Terminal filtration of petroleum products in petrochemical industry and filtration of carbon-based liquid in chemical industry.

8) High-pressure air filtration in the aerospace industry.

9) Filtration and recovery of precious metal catalysts in fine chemical industry.

10) Fuel cell electrode matrix, PEM water electrolytic cell electrode (coated Pt, etc.)

11) Catalyst carriers in gas and liquid catalytic reactions.

5. Titanium sintered porous materials allowed use environment:

Aqueous solutions of 3% hydrochloric acid, nitric acid of various concentrations, aqua regia, sea, carbonate and chloride salts, etc.

6. Precautions for the use of titanium sintered porous materials:

1) In the process of installation, disassembly and cleaning, avoid scratching, touching, smashing and other damage of hard objects.

2) Correct installation to avoid reverse filtering. Avoid instant rapid pressurization when the filter element is working.

3) When the filtration efficiency is less than 50%, the filter element should be cleaned in time.

4) When cleaning the filter element, first use pure gas back blowing, back blowing gas pressure is 1.5 times of the working pressure, each time back blowing time 3-5 seconds, back blowing 4-6 times, and then use clean liquid back washing 3-5 minutes, repeated 2-3 times.

5) If the filter element is not effective after online backblowing and backwashing, it should be removed in time for cleaning.

7. Cleaning method of titanium sintered porous materials

1) The decarbonized filter element of pharmaceutical and chemical industry mainly adopts the backblowing, backwashing method and combined with ultrasonic cleaning effect is good.

2) The filter element in the water production industry mainly uses 5% concentration of nitric acid to soak and rinse.

3) According to the chemical properties of the impurities, the raw liquid filter element shall be pickling (5% concentration of nitric acid) or alkali washing, and then washing and ultrasonic cleaning after soaking.

List of Major Products